Characteristics of MMS Materials

- Light weight: core is made from compacted aluminum powder (from 97 to almost 100% dense)

- High thermal and electrical conductivity

- Easy machinability: Allows for conventional cutting and joining methods.

- Can be cladded with sheet metal of various types such as aluminum, carbon steel, stainless steel and titanium

- Recyclable

Characteristics of AFS Materials

- Ultra-light weight: high stiffness to weight ratio (3 times that of aluminum, and 5 times lighter than steel).

- High energy absorption capability: Excellent energy absorption properties under high velocity impact due to progressive collapse of the bubble structure; can be further enhanced through alloys and reinforcement of the foam core.

- High Structural Integrity: 35% less dense than the parent metal, while preserving the mechanical properties of the parent for structural application.

- Heat and Fire Resistance: Operation at higher operating temperatures without loss of structural properties; fire retardant.

- Low thermal and electrical conductivity

- Good acoustical damping: Enables use for sound barriers.

- Easy machinability: Allows for conventional cutting and joining methods.

- Electromagnetic Shielding: Achieved through a combination of Aluminum foam and special steel

- Can be cladded with sheet metal of various types such as aluminum, carbon steel, stainless steel and titanium.

- Recyclable

SANDWICH STRUCTURES

Sandwich / Semi Sandwich:

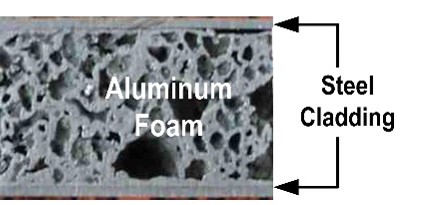

The aluminum composite sandwich consists of an aluminum foam matrix compressed between two metal cladding layers. It can also be reinforced with discrete metallic and/or carbon fiber. The outer cladding layer can be aluminum, steel, stainless steel or titanium on both sides (or any combinations of these materials). The thickness of the cladding layer can vary from 0.5-6 mm, whereas the sandwich thickness can vary from 8 to 45 mm. Semi-sandwiches consist of an aluminum-based foam core matrix with only one metal cladding layer..

Multilayer Sandwich:

Multilayer Sandwich foam is a combination of several alternating layers of aluminum foam and metallic materials assembled as a composite. Such combinations provide the multilayer sandwich unique intrinsic properties, such as greater impact absorption for blast and ballistic protection.